Cryovials, also known as cryogenic vials, are essential in the field of bioscience for storing and preserving biological samples at extremely low temperatures. These tools are vital for research, diagnostics, and development, but as the demand for effective storage solutions grows, so does the need for innovation in their design. Recent advancements have transformed traditional cryogenic vials into highly efficient tools that not only ensure sample integrity but also simplify workflows and enhance accessibility. This article explores four key innovations in cryovial design that are revolutionizing sample preservation.

Table of contents:

Advances in Cap Sealing Technologies for Leak Prevention

Incorporation of Color-Coded Caps for Easy Identification

Development of Self-Standing Vial Bases for Stability

Integration of Barcode Labels for Efficient Tracking

One of the most critical factors in cryovial performance is ensuring airtight sealing to prevent leaks in extreme conditions. Recent advancements in cap sealing technologies have made cryovials more reliable than traditional cryogenic vials. Innovations like external threads and precision-engineered caps have significantly reduced the risk of contamination and evaporation. Enhanced sealing also minimizes the risk of frost buildup, which can compromise sample quality. For researchers and laboratories dealing with highly sensitive samples, the improved leak prevention in these state-of-the-art cryovials represents a major step forward in maintaining sample integrity.

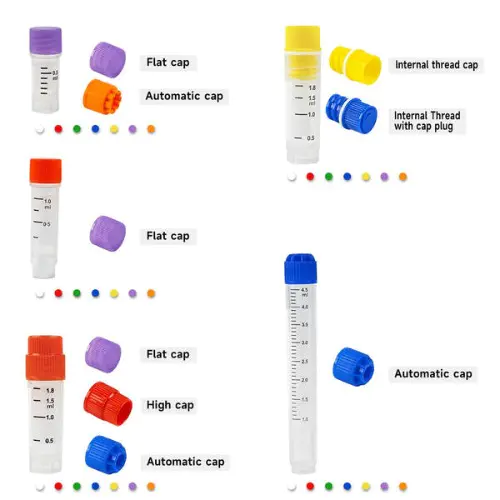

Efficient sample organization is crucial in any research environment, and the integration of color-coded caps in cryovial design addresses this need effectively. By offering caps in various colors like red, yellow, blue, green, and white, cryovials enable quick identification and categorization of samples. This seemingly simple yet highly impactful innovation reduces the time spent searching for specific samples, particularly in large biobanks or laboratories. For organizations seeking streamlined workflows, color-coded caps ensure a higher degree of accuracy and efficiency.

Traditional cryogenic vials often require racks or additional holders to ensure stability, which can be cumbersome in busy lab settings. The development of self-standing vial bases is a game-changer in this regard. These bases allow cryovials to remain stable on flat surfaces without the need for external supports. This innovation not only increases convenience during sample handling but also reduces the risk of accidents, such as spills or cross-contamination. Self-standing vials are particularly beneficial in high-throughput environments, where speed and safety are paramount.

The integration of barcode labels into cryovial design has made sample tracking and management significantly more efficient. Advanced cryovials now come equipped with unique barcodes that can be scanned for instant access to critical sample information, including origin, date of collection, and storage conditions. This innovation eliminates manual documentation errors and enhances traceability, making it easier for researchers and lab technicians to manage large inventories. Barcode-enabled cryovials are a must-have for any facility aiming to optimize its data management and sample tracking processes.

The evolution of cryovial technology demonstrates how innovation can address the growing needs of the scientific community. With enhanced cap sealing technologies, color-coded caps, self-standing bases, and barcode labels, modern cryovials are setting new standards in sample preservation. These advancements not only ensure the integrity of biological samples but also improve efficiency and organization in laboratories and biobanks. For researchers, these innovations translate into more reliable results and streamlined workflows. To explore the full range of advanced cryogenic vials and their capabilities, visit the Rongda Biotechnology product page.